Top Benefits of Using a Press Brake Machine for Metal Fabrication

In the world of metal fabrication, efficiency and precision are paramount, making the choice of machinery a crucial consideration for manufacturers. One such invaluable tool is the press brake machine, an essential equipment piece that shapes and bends metal sheets with remarkable accuracy. As noted by industry expert John Anderson, "The integration of advanced press brake machines can dramatically enhance the workflow in a fabrication shop, transforming raw materials into precise components faster than ever before."

The versatility of a press brake machine allows operators to create a wide range of shapes and angles, catering to various applications across multiple industries. From automotive components to architectural elements, the benefits of utilizing this machine extend beyond mere functionality to include increased productivity and reduced labor costs. Understanding the myriad advantages of a press brake machine not only helps businesses optimize their processes but also positions them competitively in an ever-evolving marketplace.

As we delve into the top benefits of using a press brake machine for metal fabrication, it becomes clear that this piece of equipment is more than just a tool; it is a pivotal element that drives efficiency, precision, and innovation in the metalworking industry.

Advantages of Precision Bending in Metal Fabrication

Precision bending in metal fabrication offers numerous advantages that significantly enhance the efficiency and quality of production processes. One of the primary benefits is the ability to achieve highly accurate angles and dimensions. This level of precision is crucial for industries where tight tolerances are required, such as aerospace, automotive, and architectural sectors. With advanced press brake machines, manufacturers can produce consistently reliable components, reducing the need for rework and ensuring that parts fit together seamlessly.

Additionally, precision bending optimizes material usage, minimizing waste and lowering costs. By accurately calculating the bend allowances and minimizing scrap material, manufacturers can utilize raw materials more effectively. This efficiency not only results in cost savings but also contributes to more sustainable production practices. Furthermore, precision bending enhances the overall functionality and performance of the finished products, ensuring they meet the required specifications and standards. As a result, embracing precision bending in metal fabrication can lead to improved product quality, greater customer satisfaction, and enhanced competitive advantage in the marketplace.

Enhancing Production Efficiency with Press Brake Machines

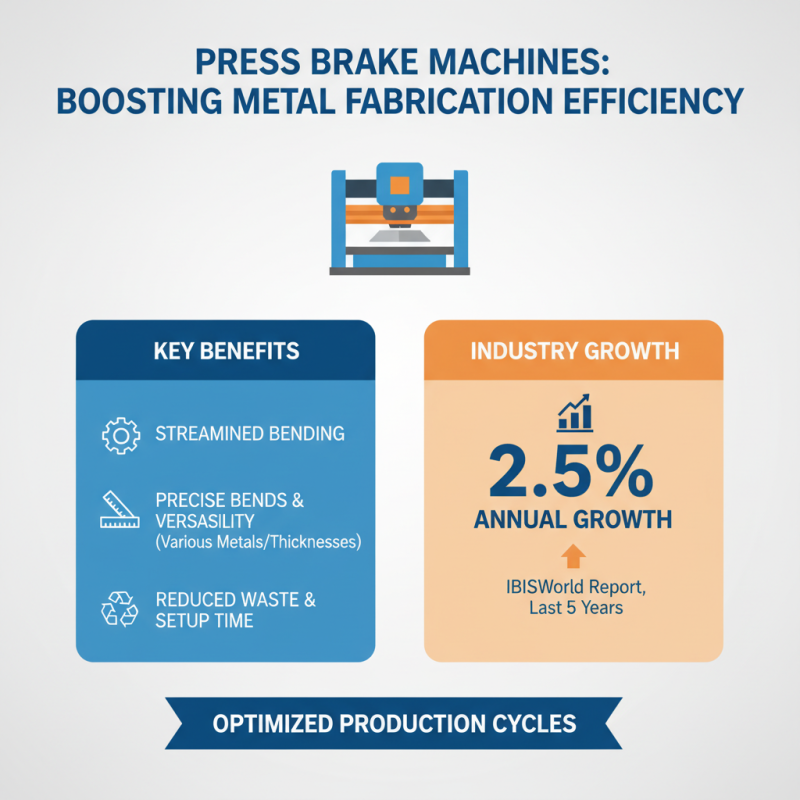

The use of press brake machines in metal fabrication significantly enhances production efficiency, providing manufacturers with a versatile tool that streamlines bending processes. According to a report by IBISWorld, the metal fabrication industry has experienced a steady growth rate of approximately 2.5% annually over the past five years, largely due to advancements in machinery like press brakes. These machines allow for precise bending of metal sheets, accommodating a variety of thicknesses and materials, which reduces setup time and material waste, ultimately leading to optimized production cycles.

Moreover, modern press brake machines often feature advanced technologies, such as CNC (Computer Numerical Control) systems, which enable automated programming for complex bends. A study by Research and Markets indicates that integrating automation in metal fabrication can increase production speed by up to 40%, illustrating the efficiency gains that come with adopting cutting-edge machinery. This level of automation not only minimizes human error but also allows manufacturers to meet tighter deadlines and fulfill larger orders, making press brakes an indispensable asset in maintaining competitive advantage within the industry.

Improving Material Versatility in Metalworking Processes

The versatility of materials in metalworking processes significantly enhances the capabilities of fabricators, and using a press brake machine plays a crucial role in this. By enabling operators to bend, shape, and manipulate various types of metals, press brakes allow for a broad spectrum of applications. This adaptability is particularly beneficial when working with diverse metal thicknesses and types, from aluminum and steel to more complex alloys. The machine’s ability to accommodate different bending angles and radii provides fabricators with the precision needed to meet specific project requirements.

Moreover, the use of a press brake machine empowers metalworkers to innovate in their designs. As the machine can handle multiple shapes and profiles, it enables the creation of intricate parts that would be challenging to achieve with other methods. This flexibility not only facilitates customized solutions for clients but also streamlines the production process, reducing material waste and improving overall efficiency. By improving material versatility, press brakes contribute to a more dynamic and responsive metalworking environment, ultimately enhancing the quality of the final products.

Cost Savings Achieved Through Automated Bending Solutions

Automated bending solutions offered by press brake machines have revolutionized the metal fabrication industry, significantly contributing to cost savings. With the precision and efficiency of modern machinery, manufacturers can reduce labor costs as fewer operators are needed to achieve the same output. This not only streamlines the production process but also minimizes the potential for human error, ensuring higher quality bends with less material waste.

Additionally, the ability to program complex bends and angles into automated systems allows for faster production cycles. This means that businesses can meet market demands quickly without sacrificing quality, leading to increased customer satisfaction and repeat orders. Over time, the initial investment in a press brake machine is often recouped through reduced operational costs and improved productivity, making it a financially sound choice for metal fabrication operations aiming to remain competitive.

Top Benefits of Using a Press Brake Machine for Metal Fabrication - Cost Savings Achieved Through Automated Bending Solutions

| Benefit | Description | Cost Savings (%) | Time Efficiency (Hours Saved) | ROI Period (Months) |

|---|---|---|---|---|

| Increased Precision | Automated bending ensures accurate angles and repeatability. | 15% | 10 | 6 |

| Reduced Waste | Minimizing scrap material through accurate cuts. | 20% | 8 | 8 |

| Labor Savings | Automation reduces the need for manual labor in bending operations. | 25% | 12 | 4 |

| Faster Production | Automated machines can operate continuously, speeding up the production process. | 30% | 15 | 5 |

| Enhanced Flexibility | Easily adapt to various designs and specifications, reducing downtime. | 10% | 5 | 3 |

Meeting Complex Design Requirements with Press Brake Technology

The advancement of press brake technology has significantly enhanced the capabilities of metal fabrication, particularly in meeting complex design requirements. A press brake machine enables operators to create precise bends and forms in metal sheets, which is essential for producing intricate components that modern industries require. According to a market research report by Grand View Research, the global market for press brake machines is projected to reach $3.5 billion by 2025, reflecting a growing demand for solutions that can handle sophisticated metal shapes.

With the ability to utilize CNC (Computer Numerical Control) systems, modern press brakes offer precision and repeatability that are crucial for high-stakes projects. These machines can accommodate varying thicknesses and types of metals while still maintaining the accuracy required for complex geometries. A study conducted by the Fabricators & Manufacturers Association highlights that 70% of manufacturers cited increased complexity in metal designs as a primary challenge, which is directly addressed by the capabilities of advanced press brake machines. This technology not only streamlines the production process but also ensures that fabricators can meet specific customer demands while minimizing material waste and operational costs.

Top Benefits of Using a Press Brake Machine for Metal Fabrication

Related Posts

-

10 Best Press Brakes for Precision Metal Bending in 2023

-

2025 How to Choose the Best Press Brake for Your Metalworking Needs

-

Why Understanding Press Brakes is Essential for Metal Fabrication Success

-

The Comprehensive Ultimate Guide to Understanding and Choosing the Right Press Brake

-

7 Digital Tips for Choosing the Perfect CNC Plasma Cutting Machine for Your Business

-

How to Choose the Best Plasma Cutting Machine for Your Business Needs