How to Choose the Best Iron Worker Machine for Your Projects

When it comes to tackling various metalworking projects, selecting the right tools is crucial for achieving optimal results. Among these tools, the iron worker machine stands out as an essential piece of equipment, known for its versatility and efficiency in performing tasks such as shearing, punching, and notching. However, with a plethora of options available in the market, choosing the best iron worker machine for your specific needs can be daunting.

In this guide, we will explore the key factors to consider when selecting an iron worker machine, ensuring that you make an informed decision tailored to your projects. From understanding the machine's capabilities to evaluating safety features and ease of use, we aim to provide insights that will empower you to invest in a machine that enhances your productivity and quality of work. Whether you are a seasoned professional or a DIY enthusiast, the right iron worker machine can make all the difference in achieving your desired outcomes in metal fabrication.

Understanding Different Types of Iron Worker Machines

When it comes to selecting an iron worker machine, it's essential to understand the different types available and their respective capabilities. The most common types include hydraulic and mechanical machines.

Hydraulic iron workers are known for their versatility and power, making them ideal for cutting, punching, and bending a wide range of materials. They often come equipped with various attachments, allowing users to perform multiple tasks with the same machine, which can be a significant advantage for workshops with diverse projects.

On the other hand, mechanical iron workers tend to be faster and are suitable for high-volume production. These machines utilize a flywheel mechanism, providing continuous operation and efficiency for repetitive tasks. While they may have a more limited range of functions compared to hydraulic models, they excel in specific applications where speed and precision are paramount.

Understanding the differences between these types will help you determine which iron worker machine aligns best with your project requirements and workflow.

Key Features to Consider When Selecting an Iron Worker Machine

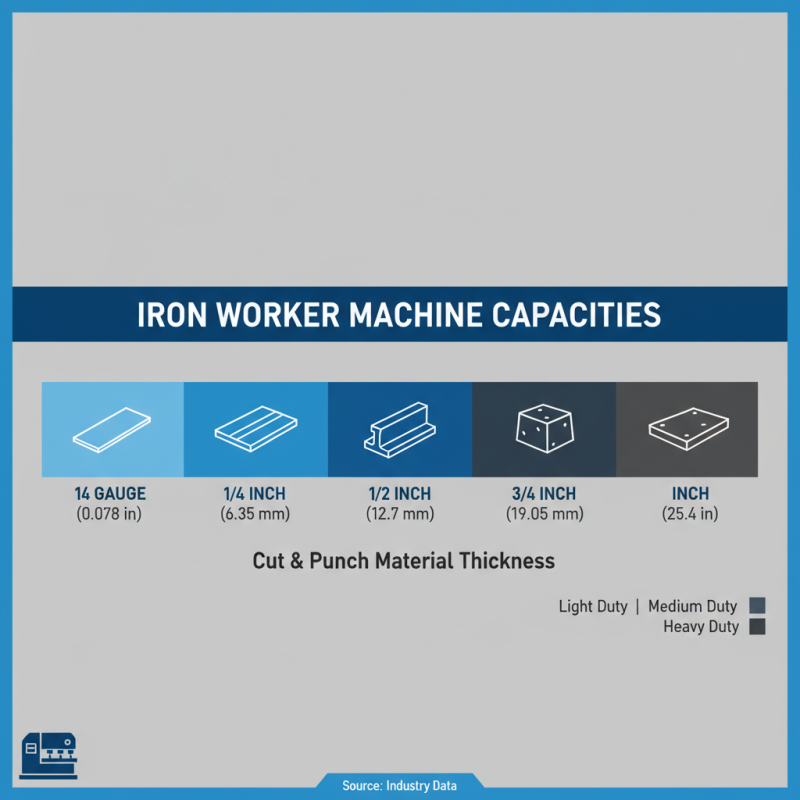

When selecting the best iron worker machine for your projects, several key features must be evaluated to ensure optimal performance and efficiency. One of the most critical factors is the machine's capacities, particularly regarding the thickness of material it can handle. According to industry data, iron worker machines can cut and punch materials ranging from 14-gauge to 1-inch thickness, depending on the model. Assessing your specific project requirements against these specifications can prevent costly errors and downtime.

Another important feature to consider is the machine’s operational versatility. Many modern iron workers offer multiple functions, such as shearing, punching, and notching, often integrated into a single unit. This multifunctionality not only increases productivity but also reduces the need for multiple machines, resulting in substantial cost savings. Recent reports suggest that companies utilizing multifunctional iron worker machines have reported up to a 30% increase in workflow efficiency. Additionally, ease of use, safety features, and the availability of operator training can greatly influence the selection process, ensuring a seamless experience for workers of various skill levels.

Assessing the Power and Capacity Requirements for Your Projects

When selecting an iron worker machine, one of the most critical factors to consider is the power and capacity requirements that align with your specific projects. Understanding the type of materials you'll be working with is essential; for instance, heavier materials necessitate machines with higher power ratings. Evaluate the thickness and strength of the steel or metal you plan to manipulate, as these elements will influence the machine's required capacity. An ideal machine should not only match the maximum thickness of the metal but also provide a bit of a buffer to accommodate for varying project demands.

In addition to material considerations, assess the frequency and volume of your projects. A machine designed for high production rates should offer enhanced cycle speeds and efficiency, reducing downtime during operations. Conversely, for smaller, less frequent tasks, a machine with lower power may suffice, ultimately providing a cost-effective solution. It’s wise to consider future projects, as selecting a machine with slightly greater capacity can accommodate the growth and evolution of your needs without necessitating an immediate upgrade. Thus, careful evaluation of both power and capacity will ensure that your iron worker machine meets your projects' demands effectively.

Evaluating Brand Reliability and Customer Support Options

When selecting an iron worker machine, the reliability of the brand and the availability of robust customer support can significantly affect your project's success. According to a recent industry report from the American Welding Society, equipment downtime due to poor support can lead to losses exceeding $5,000 per day. Therefore, it's essential to assess potential manufacturers not just for their product quality, but also for their reputation in service and support.

Before making a purchase, examine customer reviews and testimonials to gauge user experiences related to brand reliability. A reliable machine should come with comprehensive user guidance, while a manufacturer known for excellent customer support can provide assistance in troubleshooting and maintenance, ensuring that your equipment operates efficiently over time. A report by the International Trade Administration indicated that companies with strong customer support see a 20% increase in customer retention, underscoring the importance of post-purchase service.

**Tips:** Always consider warranty options as they can be indicative of a brand's commitment to customer satisfaction. A longer warranty can provide peace of mind, reflecting confidence in product durability. Furthermore, check if the brand offers online resources, such as FAQs, tutorials, or a dedicated support hotline, which can facilitate easier resolution of issues that may arise during your projects.

Iron Worker Machine Features Comparison

Budgeting for Your Iron Worker Machine Purchase and Maintenance Costs

When budgeting for an iron worker machine, it is essential to account for not just the initial purchase price but also long-term maintenance costs. According to a report by the Fabricators & Manufacturers Association, the average cost of maintenance for industrial machines can range from 2-4% of the machine’s purchase price annually. This figure can significantly impact your overall project budget, especially if you plan to use the machine extensively. For example, if you invest $50,000 in an iron worker, you should anticipate setting aside $1,000 to $2,000 each year for maintenance.

Moreover, users should consider additional costs such as replacement parts, tooling, and potential upgrades to keep the machine efficient. A study by the National Association of Manufacturers indicated that approximately 70% of manufacturing businesses experienced unexpected downtime due to equipment failures, emphasizing the importance of a proactive maintenance budget. This not only affects productivity but can also lead to unanticipated expenses.

Tips: Always set aside a contingency fund of at least 10-15% of your total budget for unforeseen repairs and replacement needs. Also, consider a regular maintenance schedule that allows you to identify and resolve minor issues before they escalate, ensuring your machine operates at peak efficiency. Building these considerations into your overall budget can help you fully realize the return on investment for your iron worker machine.

Related Posts

-

The Comprehensive Ultimate Guide to Understanding and Choosing the Right Press Brake

-

Why Understanding Press Brakes is Essential for Metal Fabrication Success

-

Discover Innovations in Metal Cutting Band Saws at the 138th Canton Fair 2025: Industry Insights and Trends

-

Top Benefits of Using a Press Brake Machine for Metal Fabrication

-

5 Essential Tips for Choosing the Perfect Fiber Laser Cutter for Your Needs

-

How to Choose the Best CNC Plasma Cutter for Your Needs in 2025