2025 How to Choose the Best Press Brake for Your Metalworking Needs

When it comes to metalworking, the choice of equipment can significantly impact production efficiency and product quality. Among the various tools available, the press brake stands out as an essential machine for bending and shaping metal sheets. According to a report by MarketsandMarkets, the global press brake market is projected to reach USD 4.02 billion by 2025, growing at a CAGR of 4.5% from 2020 to 2025. This growth reflects the increasing demand for precision in metal fabrication across various industries, including automotive, aerospace, and construction.

Selecting the best press brake for your specific needs involves understanding not only the technical specifications but also the unique requirements of your projects. Factors such as tonnage, bending length, and control systems play a crucial role in determining the right equipment. Moreover, advancements in technology, such as automated and hybrid press brakes, further complicate the decision-making process. A recent survey by the Fabricators & Manufacturers Association found that 70% of metalworking companies are investing in new equipment to enhance productivity and reduce operational costs. Therefore, being well-informed about the latest trends and available options is key to making an educated choice in an increasingly competitive market.

Understanding Your Metalworking Requirements for a Press Brake

When selecting the best press brake for your metalworking needs, it's essential to first understand your specific requirements. The evolving landscape of metal fabrication now demands machines that not only bend metals accurately but do so efficiently. Modern press brakes, particularly new electric and hybrid models, have been shown to enhance productivity while reducing setup times—data indicates these advanced options can cut setup time by as much as 30%. This efficiency is crucial for businesses that operate with tight margins and fast turnaround times.

Moreover, the integration of features like automatic tool changers and double-clamp backgauges enhances processing capabilities, especially for complex bends. Research shows that companies employing smarter press brakes can reduce the incidence of production delays caused by mechanical downtime. As manufacturers increasingly look to optimize their operations, understanding your production volume and complexity of bends will guide you in choosing the right technology—whether that involves investing in high-capacity CNC models or adding robotic handling systems to streamline workflow. Adopting these innovations may very well define a company's competitive edge in an ever-demanding market.

Key Features to Consider in a Press Brake Selection

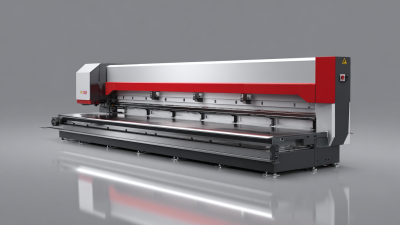

When selecting the best press brake for your metalworking needs, several key features should be carefully considered to ensure optimal performance and efficiency. First and foremost, the capacity of the press brake is crucial. This includes its tonnage, which dictates the maximum load it can handle. A higher tonnage is necessary for bending thicker materials, while a lower tonnage is sufficient for lighter gauges. Additionally, consider the working length of the machine to ensure it can accommodate the dimensions of the materials you typically handle.

Another vital feature is the control system of the press brake. Modern machines come equipped with advanced CNC (Computer Numerical Control) systems that enhance precision and repeatability. Look for features like touchscreens and programmable settings, which simplify operation and reduce setup time. Furthermore, the speed and stroke length of the press brake influence productivity; a machine that offers adjustable speeds can significantly enhance workflow when working with various materials. Lastly, explore the safety features and build quality, as these contribute to the longevity and reliable performance of the press brake in a demanding work environment.

Comparing Different Types of Press Brakes: Hydraulic vs. Mechanical

When choosing a press brake for metalworking needs, understanding the differences between

hydraulic and mechanical systems is crucial.

Hydraulic press brakes are renowned for their robust force and adaptability, making them

ideal for heavy-duty applications. They utilize hydraulic fluid to generate greater pressure, allowing for more

precise bending and shaping of metals. This system excels in handling thicker materials and offers the ability

to adjust the speed and force with great accuracy, making it a favorite among manufacturers that require

versatility and power.

On the other hand, mechanical press brakes are characterized by their simplicity

and speed. They employ mechanical linkages and cranks to transfer energy to the ram, resulting in quicker cycles

and reduced downtime. This type of press brake is generally easier to maintain and offers a cost-effective solution

for operations focused on lighter materials or less complex tasks. Ultimately, the choice between hydraulic and

mechanical press brakes will depend on specific manufacturing requirements, including material thickness,

production speed, and overall operational efficiency.

Understanding these differences can help businesses make informed decisions that align with their metalworking demands.

Tips for Assessing the Manufacturer's Reputation and Support

When selecting the best press brake for your metalworking needs, assessing the manufacturer's reputation and support is paramount. A reputable manufacturer not only provides high-quality machinery but also stands behind their products with robust customer service. Check for industry awards, certifications, and how long the company has been in business. Engaging with other metalworking professionals through forums or trade shows can yield insights into a manufacturer’s reputation.

Tips for assessing a manufacturer's reputation include reading customer reviews and testimonials. Look for feedback on their product reliability, functionality, and the overall client experience. Additionally, inquire about the level of technical support they offer. A knowledgeable support team can be invaluable in troubleshooting issues or providing assistance during installation and maintenance. It's also wise to evaluate the availability of parts and accessories, as a manufacturer with a strong supply chain can minimize downtime in your operations.

Finally, don't underestimate the importance of establishing a good relationship with your supplier. A manufacturer that prioritizes customer communication and support can make a significant difference in your long-term satisfaction and success in metalworking projects. Make sure to ask specific questions about their warranty and service options before making your investment.

Budgeting Wisely: Cost vs. Quality in Press Brake Investments

When investing in a press brake, balancing budget constraints with quality considerations is paramount. According to a report by the Fabricators & Manufacturers Association (FMA), nearly 45% of metalworking facilities cite budget limitations as a key factor when selecting machinery. However, cutting costs at the expense of quality can lead to long-term issues, diminishing productivity and increasing maintenance costs. It's essential to evaluate the total cost of ownership, which includes not only the purchase price but also operational efficiency and durability.

In a market where superior craftsmanship can increase output by up to 30%, investing in a high-quality press brake may yield returns far exceeding initial costs. Industry studies suggest that machines with robust features and reliable performance often outperform cheaper alternatives in terms of lifespan and maintenance needs. For instance, a study by Technavio indicates that quality press brakes can enhance precision and reduce waste by as much as 20%, ultimately contributing to improved profit margins. Therefore, careful budgeting that prioritizes quality can be a game changer for businesses looking to thrive in the competitive metalworking landscape.

2025 Press Brake Investment: Cost vs. Quality Analysis

Related Posts

-

10 Best Press Brakes for Precision Metal Bending in 2023

-

Why Understanding Press Brakes is Essential for Metal Fabrication Success

-

The Comprehensive Ultimate Guide to Understanding and Choosing the Right Press Brake

-

5 Digital Strategies to Enhance Your CNC Plasma Cutting Efficiency

-

How to Choose the Best Plasma Cutting Machine for Your Business Needs

-

Revolutionizing Manufacturing Efficiency with CNC Plasma Cutting Machine Innovations and Trends