Ultimate Guide to Choosing the Right Fiber Laser Cutter for Your Manufacturing Needs

In today's fast-paced manufacturing landscape, the choice of equipment can greatly influence both efficiency and product quality. Among the various cutting technologies available, the fiber laser cutter stands out as a game-changer, offering precision and versatility for a wide array of materials. This ultimate guide aims to help manufacturers navigate the complex decision-making process associated with selecting the right fiber laser cutter for their specific needs. By examining the numerous benefits of fiber laser cutting technology, from its unmatched speed and accuracy to its cost-effectiveness and minimal maintenance requirements, we'll equip you with the knowledge necessary to make an informed decision. As you delve into this guide, you will discover how the right fiber laser cutter can transform your production capabilities and drive your business forward.

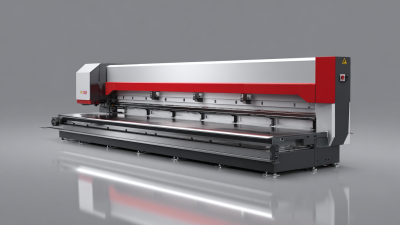

Understanding Different Types of Fiber Laser Cutters Available on the Market

When it comes to selecting the perfect fiber laser cutter for your manufacturing needs, understanding the different types available on the market is essential. Fiber laser cutters are mainly categorized based on their power output and application suitability.

For smaller projects or thin materials, low-power fiber laser cutters (ranging from 500W to 1500W) are usually sufficient. These machines excel in precision cutting for materials like thin metals, plastics, and wood, making them ideal for artisans and small manufacturers.

On the other hand, high-power fiber laser cutters (over 2000W) are designed for heavy-duty applications, allowing for faster cutting speeds and the ability to handle thicker materials, such as stainless steel or aluminum. These machines are particularly favored in industries like automotive and aerospace, where robust and intricate designs are required.

Additionally, factors such as beam quality, cutting head design, and ease of maintenance can significantly influence the performance and longevity of a fiber laser cutter, making them critical considerations when choosing the right machine for your specific manufacturing requirements.

Key Factors to Consider When Selecting a Fiber Laser Cutter

When selecting a fiber laser cutter for your manufacturing needs, understanding the key factors that influence its performance is crucial. First and foremost, consider the material types you will be cutting. Different lasers have varying capabilities when it comes to processing metals, plastics, or composites. Additionally, the thickness of the materials is a significant factor; some lasers are engineered to handle thicker materials more efficiently, while others excel in precision cutting of thinner sheets.

Another critical aspect to evaluate is the power of the fiber laser. Higher wattage lasers can cut through materials more quickly and effectively, but they also come with higher operational costs. Assess your production requirements and budget to find the right balance. Furthermore, pay attention to the laser cutter's speed and accuracy, as these will greatly affect your overall productivity and the quality of the finished products. Finally, consider the manufacturer's support and warranty options, as reliable service can significantly impact the longevity and efficiency of your equipment.

Comparison of Key Features in Fiber Laser Cutters

Comparative Analysis of Fiber Laser Cutters for Various Manufacturing Applications

When selecting the right fiber laser cutter for your manufacturing applications, it is essential to analyze various models based on specific needs. Different fiber laser cutters excel in various materials and applications, whether you’re focusing on metals, plastics, or advanced composites. For sheet metal fabrication, look for cutters with high wattage and fast cutting speeds to enhance production efficiency. On the other hand, for intricate designs in softer materials, a system with superior precision and lower power may be more suitable.

Tips: Always consider the thickness of the materials you intend to cut, as this will directly impact the choice of laser power. Moreover, investigate the maintenance requirements and service support offered by the manufacturers to ensure long-term reliability of the equipment. A holistic approach to understanding your manufacturing processes and aligning them with the right fiber laser systems can lead to optimized performance and cost savings.

When comparing models, pay attention to features such as beam quality, cutting speed, and software compatibility. The right software can greatly enhance workflow efficiency by simplifying design uploads and cutting parameters. Remember, investing time in research now can significantly improve the productivity and precision of your manufacturing operations in the long run.

Maintenance and Support for Different Types of Fiber Laser Cutters

When selecting a fiber laser cutter, understanding the maintenance and support for different types is crucial to ensure long-term efficiency and productivity. Each model may vary in its required upkeep, often depending on the technology used and the manufacturer’s guidelines. Regular maintenance tasks typically include lens cleaning, checking the cooling system, and ensuring proper alignment. Neglecting these components can lead to reduced cutting quality and increased downtime, which adversely affects manufacturing processes.

Furthermore, the level of support provided by manufacturers should be a significant consideration. Some brands offer extensive warranties and responsive customer service, including on-site assistance and training for operators. Others may provide only basic support, which could result in delays during troubleshooting. By evaluating both the maintenance demands and the available support for different fiber laser cutter options, manufacturers can make informed decisions that align with their operational requirements and minimize potential disruptions. Investing time in understanding these aspects is key to achieving optimal performance from your fiber laser cutting equipment.

Cost-Benefit Analysis of Investing in Fiber Laser Cutting Technology

Investing in fiber laser cutting technology can significantly enhance efficiency and precision in manufacturing processes. According to recent industry reports, the industrial lasers market is projected to expand substantially, with key trends suggesting a growing preference for fiber lasers due to their superior performance characteristics. By 2032, the market is expected to exhibit robust growth driven by advancements in automation and artificial intelligence, which are set to improve operational efficiency in laser cutting applications.

The cost-benefit analysis of adopting fiber laser technology reveals an attractive return on investment for manufacturers. A comprehensive analysis highlights that, while initial setup costs may be high, the long-term savings and productivity improvements can outweigh these expenditures. With the fiber laser market expected to increase in size, reaching significant growth by 2033, businesses can anticipate not only cost savings in maintenance and energy consumption but also enhanced capabilities to meet the demands of a rapidly evolving market landscape. Embracing this technology positions manufacturers to better compete, especially as global trends lean towards automation and high efficiency in production processes.

Related Posts

-

Unveiling CO2 Laser Cutting Machines A Detailed Comparison of Efficiency Cost and Precision

-

The Comprehensive Ultimate Guide to Understanding and Choosing the Right Press Brake

-

Ultimate Checklist for Choosing the Right CNC Press Brake for Your Business

-

2025 Market Insights: The Rise of the Best Laser Machine in Precision Manufacturing