5 Essential Tips for Choosing the Perfect Fiber Laser Cutter for Your Needs

In the rapidly evolving landscape of industrial manufacturing, the selection of the perfect fiber laser cutter is a pivotal decision that can significantly influence productivity and efficiency. According to a recent report by MarketsandMarkets, the fiber laser market is projected to grow from $2.3 billion in 2020 to $4.6 billion by 2025, demonstrating an impressive compound annual growth rate (CAGR) of 14.4%. As manufacturers increasingly seek to enhance cutting speeds and precision, understanding the intricacies involved in selecting the right fiber laser cutter becomes essential.

Expert insights emphasize the importance of informed decision-making in this specialized area. Dr. James Reynolds, a leading authority in laser technology, has stated, “Choosing the right fiber laser cutter is not just about specifications; it's about aligning the technology with your production goals.” This highlights the need for buyers to consider factors such as material type, thickness, and operational environment when selecting equipment. As the industry continues to innovate, having the right fiber laser cutter can be the key differentiator that propels businesses forward in a competitive marketplace.

Understanding Your Material Requirements for Fiber Laser Cutting

When selecting a fiber laser cutter, understanding your material requirements is crucial for achieving optimal results. Different materials respond distinctly to laser cutting, and knowing their properties can significantly influence your choice. For instance, metals like stainless steel and aluminum require higher power settings, while materials such as acrylic or wood may demand less intense energy. According to a report by the Laser Institute of America, fiber lasers are particularly effective for cutting thin to medium-thickness metals, achieving speeds up to 10 times faster than traditional methods. This speed can notably increase productivity, especially in industries that rely heavily on precise cuts.

Tip 1: Always consider the thickness of the materials you plan to cut. A fiber laser cutter's power rating should be aligned with the maximum thickness of the material to ensure efficiency and avoid wear on the machine. For example, a 1000W fiber laser can typically cut up to 5mm of stainless steel effectively, while a 3000W cutter can handle thicker sections, providing suppliers with greater versatility.

Tip 2: Material composition plays a significant role. It's essential to differentiate between various metals, as their melting points and reflection properties vary. For example, certain alloys may require specialized settings to prevent excessive heating that can warp the product. Additionally, consider incorporating a cooling mechanism in your cutting setup to help maintain the integrity of sensitive materials throughout the process. By tailoring your fiber laser cutter to your specific material requirements, you’ll achieve better efficiency and ultimately save costs in production.

Evaluating the Power Output and Performance of Fiber Laser Cutters

When selecting a fiber laser cutter, one of the most critical aspects to consider is its power output. The power level of a fiber laser cutter significantly affects its cutting speed, material compatibility, and overall efficiency. Typically, higher wattage machines can cut through thicker materials more quickly, thus enhancing productivity in industrial settings. Understanding the specific materials you plan to work with will help determine the appropriate power output needed to achieve optimal results.

In addition to power, performance factors such as beam quality and operational stability play vital roles in the effectiveness of a fiber laser cutter. A well-focused beam allows for cleaner cuts and finer details, which is particularly important for intricate designs. Furthermore, consistent performance, particularly over extended periods, is essential to maintain high-quality outputs without interruptions. Evaluating these specifications while considering your specific cutting applications will ensure that the fiber laser cutter you choose not only meets your current needs but also has the capability to adapt to future projects.

Key Features to Look for in a Fiber Laser Cutter

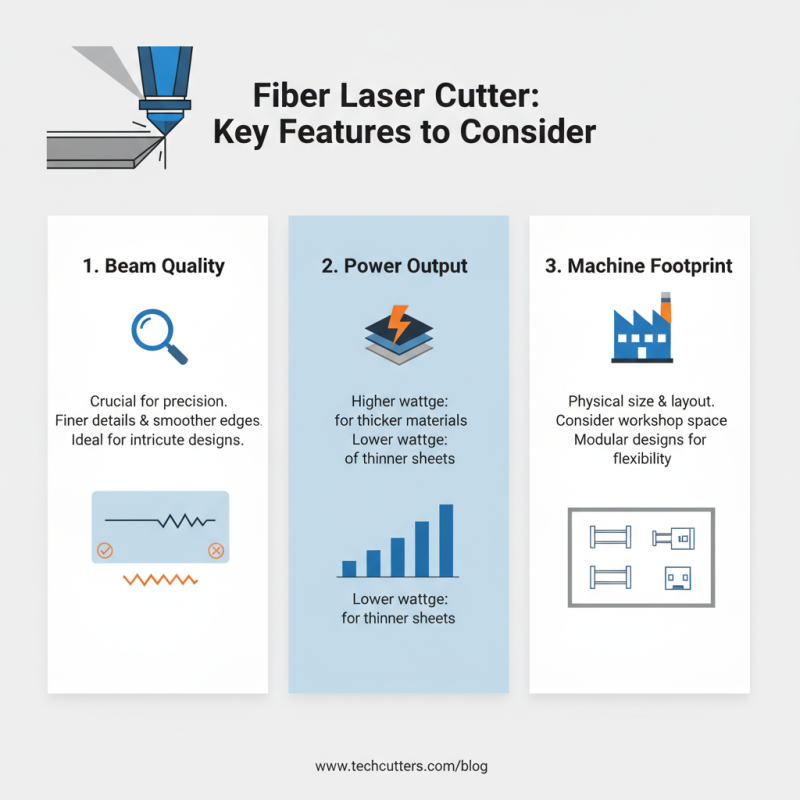

When selecting a fiber laser cutter, several key features must be taken into account to ensure it meets your specific needs. Firstly, beam quality is crucial, as it directly affects the precision of your cuts. A high-quality beam will result in finer details and smoother edges, making it ideal for intricate designs. Additionally, consider the power output of the machine; higher wattage is necessary for cutting thicker materials, while lower power might suffice for thin sheets.

Another important aspect is the cutting area size, which should align with the dimensions of the materials you plan to work with. A spacious cutting bed can accommodate larger projects without requiring additional setups, enhancing productivity. Furthermore, the machine's ease of use and software compatibility should not be overlooked. User-friendly interfaces and integrated software solutions streamline the cutting process and reduce the learning curve, making it easier for operators to achieve consistent results. By prioritizing these features, you can choose a fiber laser cutter that effectively meets your production demands.

Assessing Budget Considerations for Your Fiber Laser Cutter Purchase

When considering the purchase of a fiber laser cutter, budget is undoubtedly a crucial factor that can significantly influence your decision. Begin by determining how much you're willing to invest in this equipment. Fiber laser cutters come in a range of prices, typically influenced by their capabilities, power, and features. Establishing a clear budget at the outset allows you to focus your search on machines that fulfill your requirements without overspending.

Additionally, consider the long-term costs associated with the fiber laser cutter. This includes maintenance, replacement parts, and operational expenses like electricity and materials. While a lower initial cost may seem appealing, it’s essential to account for these ongoing expenses, which can add up over time. Investing in a more efficient and reliable machine may lead to savings in the long run, both in terms of maintenance and energy consumption. Therefore, a careful assessment that encompasses both initial purchase price and ongoing operational costs is vital in ensuring that you select the perfect fiber laser cutter for your needs while staying within your financial parameters.

Reviewing Customer Support and Warranty Options for Fiber Laser Cutters

When selecting a fiber laser cutter, customer support and warranty options play a crucial role in ensuring long-term satisfaction and operational efficiency. According to the Laser Institute of America, a well-structured support system not only enhances user experience but also minimizes downtime during production. Many manufacturers offer comprehensive support that includes technical assistance, troubleshooting, and regular software updates, which are vital in a field where technology is rapidly evolving. Research highlights that companies with robust customer service are 50% more likely to retain clients, emphasizing the importance of responsive and accessible support.

In addition to customer support, warranty options are a significant consideration for buyers. A typical warranty for fiber laser cutters ranges from one to three years, but the specifics can vary widely. A survey by the International Laser Safety Conference found that around 70% of businesses prioritize extended warranty options, particularly for high-value equipment, as it provides peace of mind and protects against unforeseen repair costs. A comprehensive warranty should cover critical components, including the laser source, to safeguard your investment. Choosing a manufacturer that not only offers strong warranty terms but also provides ongoing training and support can greatly enhance the overall experience of using fiber laser technology.

5 Essential Tips for Choosing the Perfect Fiber Laser Cutter for Your Needs - Reviewing Customer Support and Warranty Options for Fiber Laser Cutters

| Feature | Description | Customer Support Options | Warranty Duration |

|---|---|---|---|

| Cutting Thickness | Ability to cut materials of varying thicknesses, typically up to 25mm for metals. | 24/7 phone and email support; on-site assistance available. | 2 years on laser source; 1 year on other components. |

| Software Compatibility | Compatible with various CAD and CAM software for easy design integration. | Online resources and tutorials; live chat available during business hours. | 2 years for electronics; optional extended warranty available. |

| Size and Portability | Compact models available for smaller workshops; larger models for industrial use. | Dedicated customer service team for machine installation and relocation. | 1 year for mobility components; optional additional coverage for transport damage. |

| Cooling System | Effective cooling systems to enhance performance and prolong lifespan of components. | Regular maintenance advice and cooling system check-up services offered. | 2 years; includes parts related to the cooling system. |

| Cost of Ownership | Considerations for maintenance, operation costs, and potential energy efficiency. | Cost estimation consultation services available. | Standard warranty applies, with flexible plans for future maintenance. |

Related Posts

-

Ultimate Guide to Choosing the Right Fiber Laser Cutter for Your Manufacturing Needs

-

Revolutionizing Precision: How Laser Metal Cutting Machines Are Transforming Industries

-

Unveiling CO2 Laser Cutting Machines A Detailed Comparison of Efficiency Cost and Precision

-

Revolutionizing Manufacturing: Innovative Solutions for CNC Laser Cutter Efficiency

-

Essential Checklist for Optimizing Your Fiber Laser Cutting Machine Performance

-

Unlocking Precision: The Future of Manufacturing with Laser Metal Cutting Machines