Top 10 Laser CNC Machine Benefits and Features You Need to Know

In today's rapidly evolving manufacturing landscape, the adoption of advanced technologies is crucial for businesses aiming to maintain a competitive edge. One such technology making significant waves in various industrial sectors is the laser CNC machine. This innovative tool combines the precision of computer numerical control with the power of laser cutting, elevating the efficiency and quality of production processes to new heights.

The benefits of utilizing a laser CNC machine extend beyond mere speed; they encompass enhanced accuracy, versatility, and the ability to work with a wide range of materials. This introduction sets the stage for exploring the top ten benefits and features of laser CNC machines, providing insights into how they can transform manufacturing operations. From minimizing waste to offering intricate design capabilities, understanding these key aspects is essential for anyone looking to harness the power of laser technology in their production workflow. Whether you are a seasoned industrial professional or a newcomer to CNC technology, appreciating the advantages that laser CNC machines bring can lead to smarter, more efficient manufacturing practices.

Overview of Laser CNC Machines and Their Applications

Laser CNC machines have revolutionized various industries by integrating laser technology with computer numerical control. These machines utilize highly focused beams of light to cut, engrave, or mark materials with exceptional precision and speed. The versatility of laser CNC machines allows them to work seamlessly with a wide variety of materials, including metals, plastics, wood, and glass. This adaptability makes them an invaluable tool in manufacturing, signage, and decorative applications, among others.

In addition to their diverse material compatibility, laser CNC machines are renowned for their accuracy and repeatability. The computer-controlled operation ensures that every cut or engraving maintains consistent quality, which is crucial in mass production scenarios. Furthermore, the non-contact nature of laser cutting minimizes the risk of material distortion or damage, providing a clean edge and enhancing the overall finish of the product. Laser CNC machines also contribute to increased efficiency, often reducing production time while maintaining superior results, ultimately leading to higher productivity and cost savings for businesses across different sectors.

Key Benefits of Using Laser CNC Technology in Manufacturing

Laser CNC technology has revolutionized the manufacturing landscape, offering numerous advantages that enhance productivity and efficiency. One of the key benefits is precision. According to a report by MarketsandMarkets, the global CNC machine market is projected to grow from $62.55 billion in 2020 to $100.66 billion by 2025, driven largely by advancements in laser cutting technologies. Laser CNC machines are capable of achieving cutting tolerances of up to ±0.1mm, which significantly outperforms traditional machining methods. This precision allows manufacturers to create intricate designs and highly detailed components that are essential in industries such as aerospace and automotive.

Another noteworthy benefit of laser CNC technology is its versatility. The ability to process various materials—whether metals, plastics, or wood—without the need for extensive retooling makes it an ideal solution for manufacturers facing diverse production needs. A report from IBISWorld indicates that the metal cutting and processing industry will continue to expand, with laser technology being a key driver of this growth. Moreover, laser CNC machines can operate at much higher speeds compared to conventional methods, reducing cycle times and improving overall production efficiency. This combination of speed, accuracy, and flexibility positions laser CNC technology as a cornerstone in modern manufacturing processes, enabling companies to remain competitive in an ever-evolving market.

Essential Features to Look for in a Laser CNC Machine

When choosing a laser CNC machine, there are several essential features to consider that can significantly impact your production capabilities and efficiency. One of the most crucial elements is the power of the laser. Machines with higher wattage can cut through thicker materials with ease, enhancing versatility for a variety of projects. Additionally, it’s important to look for machines with efficient cooling systems. Proper cooling helps maintain the laser’s performance during extended operations and increases the machine's longevity.

Another major aspect to evaluate is the cutting speed and precision. A machine that offers high-speed cutting while maintaining accuracy can dramatically improve productivity and reduce waste. Look for features such as automated height adjustment to ensure consistent cutting depths across different materials. Lastly, consider the software compatibility and user interface. An intuitive control panel and supportive software make programming and operating the laser CNC machine more accessible, allowing for a smoother workflow and quicker learning curve for operators. These features collectively determine the machine’s effectiveness in meeting your specific needs.

Comparative Analysis: Laser CNC vs. Traditional Machining Methods

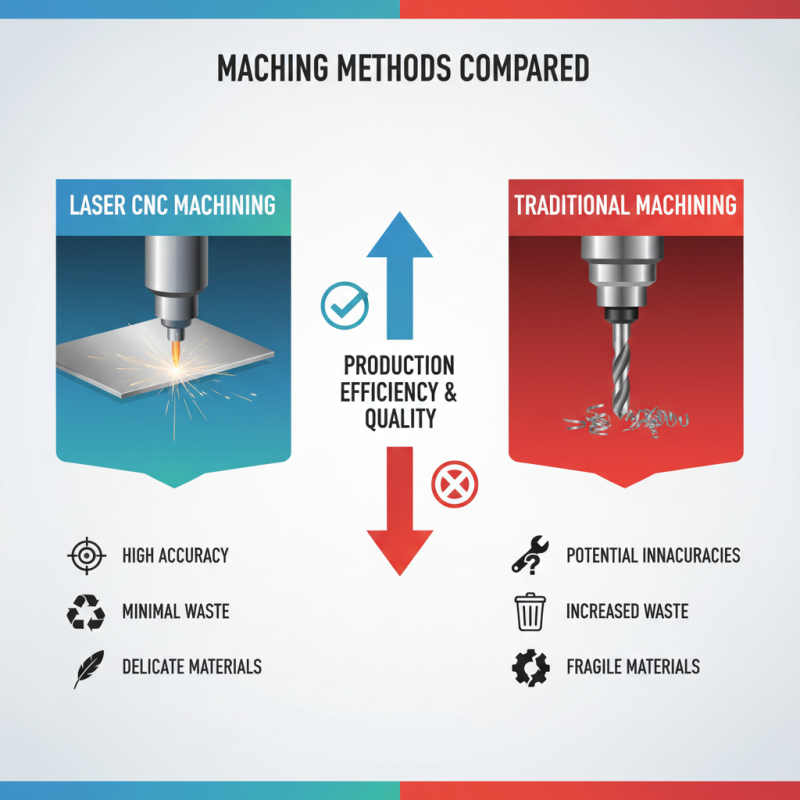

When comparing laser CNC machining with traditional machining methods, key differences emerge that can significantly impact production efficiency and product quality. Laser CNC machines utilize a concentrated beam of light to cut, engrave, and mark materials with precision, resulting in high accuracy and minimal material waste. In contrast, traditional machining often relies on mechanical tools that can introduce more variables, leading to potential inaccuracies and increased waste. The non-contact nature of laser machining allows for easier handling of delicate materials that might be too fragile for conventional techniques.

Additionally, the speed and adaptability of laser CNC machines provide a competitive edge over traditional methods. Laser machines can rapidly process a variety of materials, adjusting settings on-the-fly to accommodate different thicknesses and types without the need for physical tool changes. This agility not only reduces downtime but also enables manufacturers to respond more quickly to design modifications or custom orders. Traditional machining, while effective for certain applications, typically requires more setup time and physical adjustments, which can slow down production processes and hamper efficiency, particularly in fast-paced manufacturing environments.

Future Trends in Laser CNC Technology and Their Impact on Industry

The landscape of laser CNC technology is undergoing rapid transformation, with significant implications for various industries. As highlighted in recent reports, the global laser cutting machine market is expected to reach $5.21 billion by 2027, growing at a compound annual growth rate (CAGR) of 4.75%. This growth is driven by advancements in laser technology, which enhance precision and speed in manufacturing processes. Industries are increasingly adopting laser CNC machines for applications such as metal fabrication, automotive components, and intricate design work, reflecting a shift towards automation and efficiency.

Future trends indicate a greater integration of artificial intelligence and machine learning with laser CNC systems, further improving operational efficacy. By utilizing predictive analytics, these systems can optimize cutting operations in real-time, reducing waste and enhancing material utilization. According to a report by MarketsandMarkets, the adoption of smart manufacturing technologies, including laser CNC machines, is projected to boost productivity by 20-30% in sectors embracing Industry 4.0 initiatives. As industries evolve, the capability of laser CNC machines to provide precise and adaptable manufacturing solutions positions them as key players in achieving competitive advantage in the marketplace.

Top 10 Laser CNC Machine Benefits and Features You Need to Know

| Benefit/Feature | Description | Industry Impact |

|---|---|---|

| Precision Cutting | Laser CNC machines provide high precision in cutting materials, allowing for intricate designs. | Reduces waste and improves product quality across industries like automotive and aerospace. |

| Versatility | Can cut or engrave a wide variety of materials including metals, plastics, and wood. | Enables companies to expand their product offerings and customize solutions. |

| Speed | Laser cutting is faster than traditional methods, enhancing production efficiency. | Helps companies meet tight deadlines and increase overall output. |

| Minimal Material Distortion | Uses a focused laser beam which minimizes heat-affected zones, reducing warping. | Improves part integrity and reduces re-work or scrappage costs. |

| Automation Capability | Easily integrates with automated systems for seamless production. | Increases automation in factories and reduces labor costs. |

| Low Operating Costs | Lower energy consumption compared to other CNC cutting methods. | Enhances profitability through cost-effective manufacturing processes. |

| Safety Features | Often equipped with safety enclosures and sensors for operator protection. | Lowers the risk of workplace accidents and injury liabilities. |

| Software Integration | Compatible with advanced design software for streamlined workflow. | Enhances design capabilities and efficiency in project execution. |

| Future Trends | Advancements in AI and IoT will enhance laser cutting technologies. | Potential for new applications and improved operational efficiencies. |

Related Posts

-

Revolutionizing Manufacturing: Innovative Solutions for CNC Laser Cutter Efficiency

-

Unveiling CO2 Laser Cutting Machines A Detailed Comparison of Efficiency Cost and Precision

-

Ultimate Guide to Choosing the Right Fiber Laser Cutter for Your Manufacturing Needs

-

5 Digital Strategies to Enhance Your CNC Plasma Cutting Efficiency

-

Top Benefits of Using a Press Brake Machine for Metal Fabrication

-

2025 Market Insights: The Rise of the Best Laser Machine in Precision Manufacturing