How to Maximize Efficiency with Fiber Laser Cutting Machines

In the rapidly evolving manufacturing landscape, optimizing production efficiency has become paramount, particularly in the realm of metal fabrication. A key player in this transformation is the fiber laser cutting machine, which has gained prominence due to its superior speed, precision, and cost-effectiveness. According to a report by MarketsandMarkets, the fiber laser market is projected to grow from $2.1 billion in 2021 to $4.5 billion by 2026, highlighting the increasing adoption of this technology among manufacturers. The ability of fiber laser cutting machines to achieve cutting speeds up to 80% faster than traditional CO2 lasers and deliver a remarkable reduction in operational costs makes them an invaluable asset. By effectively harnessing the power of fiber laser technology, businesses can not only enhance their production capabilities but also reduce waste and energy consumption, solidifying their competitive edge in an increasingly demanding marketplace.

Understanding the Basics of Fiber Laser Cutting Technology

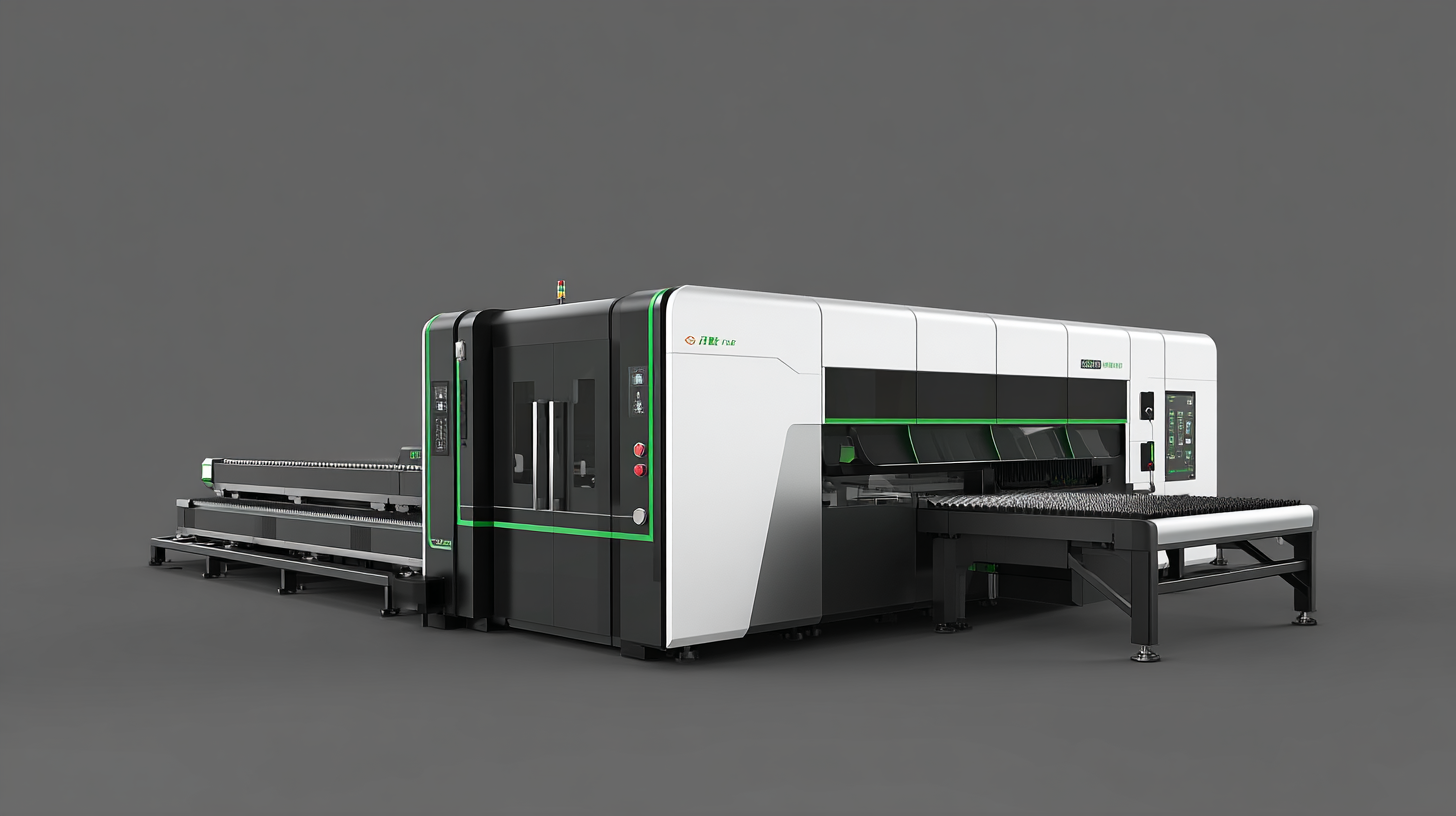

Fiber laser cutting technology has revolutionized the manufacturing sector with its precision and efficiency. Understanding the basics of this technology is crucial for maximizing the capabilities of fiber laser cutting machines. These systems utilize highly focused beams of light to cut through materials, offering exceptional speed and accuracy compared to traditional methods. The advantages of fiber lasers include lower operational costs, reduced maintenance requirements, and improved energy efficiency, which are pivotal for modern production environments.

Fiber laser cutting technology has revolutionized the manufacturing sector with its precision and efficiency. Understanding the basics of this technology is crucial for maximizing the capabilities of fiber laser cutting machines. These systems utilize highly focused beams of light to cut through materials, offering exceptional speed and accuracy compared to traditional methods. The advantages of fiber lasers include lower operational costs, reduced maintenance requirements, and improved energy efficiency, which are pivotal for modern production environments.

To enhance your efficiency with fiber laser cutting machines, consider these tips: First, always ensure that the machine is calibrated correctly and maintained regularly to avoid unplanned downtime. Second, select the right type of fiber laser for your specific applications; for instance, the choice between solid-state lasers or semiconductor lasers can greatly influence performance. Third, optimize your workflow by using advanced software that integrates design and cutting processes seamlessly, thereby reducing material waste and improving turnaround times.

Additionally, staying informed about market trends can also contribute to better decision-making. As the global fiber laser market is projected to grow significantly in the coming years, investing in the latest technology and training will position your operations for future success. Understanding these fundamentals will pave the way for effective use of fiber laser cutting technology in any production setting.

Choosing the Right Fiber Laser Cutting Machine for Your Needs

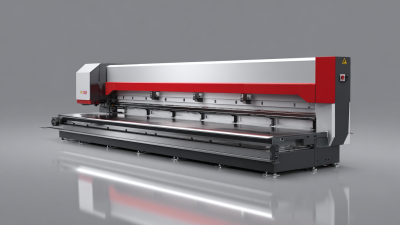

When selecting a fiber laser cutting machine, it's crucial to assess your specific needs and requirements. The first step is to determine the materials you will be cutting. Different machines offer various power levels, which can significantly impact their ability to work with thick materials or intricate designs. For instance, if your projects primarily involve thin steel or aluminum, a lower wattage machine may suffice, while heavy-duty applications might necessitate a higher wattage option for optimal performance.

Additionally, consider the size and type of the components you plan to cut. Some machines come with larger cutting beds that can accommodate bigger sheets, which is a key factor if you often work with large-scale projects.Furthermore, evaluate the machine’s software compatibility and ease of use, as a user-friendly interface can greatly enhance efficiency and reduce downtime. Reviewing customer reviews and seeking expert advice can also guide you in making an informed decision tailored to your production needs.

Optimizing Material Selection for Enhanced Cutting Efficiency

When it comes to enhancing the cutting efficiency of fiber laser cutting machines, the choice of material plays a crucial role. Different materials possess varying properties that can significantly impact the performance of the cutting process. For instance, metals such as stainless steel and aluminum respond differently to laser cutting, with factors like thickness and alloy composition affecting the speed and quality of the cut. By selecting materials that align with the laser cutting machine's capabilities and optimizing for specific thicknesses, manufacturers can achieve cleaner cuts and reduce processing time.

Additionally, utilizing advanced materials designed for laser cutting can also elevate efficiency. For example, specially coated or pre-treated metals can enhance reflectivity, allowing for better absorption of the laser energy. This approach not only improves cutting speed but also extends the lifespan of the cutting components due to reduced wear and tear. By considering these material characteristics and implementing appropriate selections, businesses can maximize their operational efficiency, resulting in higher productivity and optimized resource utilization in their laser cutting operations.

Implementing Best Practices for Machine Operation and Maintenance

Implementing best practices for machine operation and maintenance is crucial to maximizing efficiency with fiber laser cutting machines. Initially, operators should familiarize themselves with the specific machine's manual and technical guidelines. Proper training ensures that operators can make the most of the machine's capabilities, reducing errors and enhancing productivity. Regular inspection and calibration of the laser system are vital to maintain precision cuts. Neglecting these checks can lead to inconsistent results and increased material waste.

Furthermore, proactive maintenance schedules should be established to keep the fiber laser cutting machine in optimal condition. This includes routine cleaning of lenses and mirrors, checking for wear and tear in components, and ensuring that coolant levels are adequate. Maintaining an organized workspace also contributes to efficiency; a clutter-free environment allows for quick access to tools and materials, minimizing downtime. By adhering to these best practices, operators can significantly extend the lifespan of the machine while achieving high-quality cutting results.

Leveraging Software Tools for Improved Laser Cutting Workflow

Leveraging software tools effectively can greatly enhance the workflow of fiber laser cutting machines, leading to increased efficiency and precision. The integration of advanced CAD/CAM software allows for seamless design to production transitions, minimizing setup time. According to a report by the Machinery Industry Institute, companies utilizing sophisticated software solutions can reduce production time by up to 30%, significantly impacting overall output.

Furthermore, utilizing nesting software can optimize material usage, reducing waste and costs. Studies have shown that effective nesting strategies can improve material utilization by 10-15%, which not only saves money but also supports sustainability efforts within manufacturing. Additionally, real-time monitoring and analytics software enable operators to track machine performance, identify bottlenecks, and implement corrective measures swiftly. Per a recent industry analysis, businesses that employ real-time data analytics experience a 20% increase in machine uptime, further solidifying the importance of software tools in maximizing the efficiency of fiber laser cutting operations.

How to Maximize Efficiency with Fiber Laser Cutting Machines - Leveraging Software Tools for Improved Laser Cutting Workflow

| Parameter | Description | Value |

|---|---|---|

| Laser Power | Output power of the laser | 1000 W |

| Cutting Speed | Speed of the laser cutting movement | 5 m/min |

| Material Thickness | Maximum thickness of material that can be cut | 20 mm |

| Software Type | Type of software used for design and control | CAD/CAM Software |

| Feature Optimization | Software features that enhance cutting | Path optimization, nesting algorithms |

| Material Type | Types of materials suitable for laser cutting | Steel, Aluminium, Acrylic |

| Cycle Time | Time taken to complete a cutting cycle | 10 mins |

Related Posts

-

Essential Checklist for Optimizing Your Fiber Laser Cutting Machine Performance

-

Ultimate Guide to Waterjet Machine Comparison for Global Buyers

-

Ultimate Guide to Choosing the Right Fiber Laser Cutter for Your Manufacturing Needs

-

The Comprehensive Ultimate Guide to Understanding and Choosing the Right Press Brake

-

Revolutionizing Manufacturing: Innovative Solutions for CNC Laser Cutter Efficiency

-

5 Digital Strategies to Enhance Your CNC Plasma Cutting Efficiency