Revolutionizing Manufacturing: Innovative Solutions for CNC Laser Cutter Efficiency

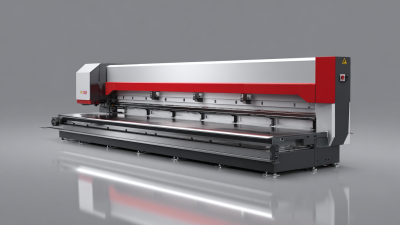

In the fast-paced world of modern manufacturing, enhancing efficiency is paramount, and one of the groundbreaking advancements in this realm is the use of CNC laser cutters. These high-precision machines have revolutionized the way materials are processed, offering unparalleled speed and accuracy while maintaining cost-effectiveness. As industries strive for innovation and productivity, the integration of advanced technologies in CNC laser cutting has emerged as a pivotal solution. This blog will explore the numerous benefits of employing CNC laser cutters in manufacturing processes, highlighting how they streamline workflows, reduce waste, and improve overall quality. By harnessing the power of these innovative tools, businesses can not only stay competitive but also push the boundaries of what's possible in manufacturing.

Join us as we delve into the transformative impact of CNC laser cutters on the industry and discover the solutions that can redefine efficiency.

Join us as we delve into the transformative impact of CNC laser cutters on the industry and discover the solutions that can redefine efficiency.

Maximizing CNC Laser Cutter Productivity: Key Metrics and Benchmarks in the Manufacturing Sector

The CNC laser cutting industry is experiencing significant growth, with the global market valued at $5.7 billion in 2023 and projected to nearly double to $13.3 billion by 2032. This impressive expansion comes with an annual growth rate of 9.9%, highlighting a robust demand for enhanced productivity and efficiency in manufacturing processes. As companies invest in these advanced technologies, it becomes crucial to establish key performance indicators (KPIs) to track their operational effectiveness and competitiveness.

Maximizing CNC laser cutter productivity involves monitoring vital metrics such as cutting speed, precision, and material waste reduction. Benchmarking these metrics against industry standards enables manufacturers to identify areas for improvement and optimize their operations. Companies must focus on integrating cutting-edge technologies and adopting sustainable practices to ensure they lead in the evolving landscape of laser cutting solutions. Emphasizing efficiency not only enhances profitability but also positions manufacturers to respond swiftly to the demands of a rapidly changing market.

Integrating AI Technologies: Enhancing Precision and Speed in CNC Laser Cutting Processes

The integration of AI technologies into CNC laser cutting processes is transforming the manufacturing landscape, significantly enhancing both precision and speed. According to a recent report by MarketsandMarkets, the global AI in manufacturing market is projected to reach $16.7 billion by 2026, growing at a compound annual growth rate (CAGR) of 49.5%. This explosive growth is driving manufacturers to adopt AI solutions to optimize their CNC laser cutting operations, resulting in reduced waste and improved accuracy.

AI algorithms can analyze vast amounts of data generated during the laser cutting process, allowing for real-time adjustments that enhance operational efficiency. A study published in a leading manufacturing journal found that integrating AI with CNC laser systems can improve cutting speed by up to 30% while simultaneously increasing the precision of cuts, reducing the margin of error to less than 0.005 inches. Furthermore, predictive maintenance powered by AI can foresee equipment failures before they occur, minimizing downtime and maintenance costs. As the industry embraces these innovative solutions, manufacturers that leverage AI are not just keeping pace but are setting the standard for efficiency and productivity in CNC laser cutting.

Revolutionizing CNC Laser Cutting Efficiency

This chart illustrates the efficiency improvements in CNC laser cutting processes after the integration of AI technologies. The data shows the percentage increase in precision and speed over a six-month period.

Energy Efficiency in Laser Cutting: Reducing Costs and Environmental Impact for Manufacturers

As the manufacturing landscape continues to evolve, energy efficiency in laser cutting has emerged as a game-changer for manufacturers seeking to reduce operational costs while minimizing their environmental footprint. CNC laser cutting, known for its precision and versatility, can often consume a significant amount of energy. However, implementing innovative technologies and optimizing processes can drastically enhance energy efficiency. By investing in advanced systems with lower power consumption requirements and features like intelligent power management, manufacturers can attain significant savings on energy bills and operational expenditures.

Furthermore, improving energy efficiency does not only translate into cost reduction. It plays a vital role in decreasing the overall environmental impact of manufacturing activities. Laser cutting machines that minimize energy waste contribute to lower carbon emissions, aligning with global sustainability goals. To achieve this, manufacturers can incorporate renewable energy sources, such as solar or wind power, into their operations, ensuring that their cutting processes are not only efficient but also eco-friendly. By prioritizing energy-efficient solutions in CNC laser cutting, manufacturers can cultivate a more sustainable future while simultaneously improving their bottom line.

Advancements in Materials: Exploring New Solutions for Improved CNC Laser Cutting Performance

The world of CNC laser cutting is undergoing a remarkable transformation, driven by advancements in materials that significantly enhance cutting performance. The introduction of high-quality, specialized materials like advanced composites and innovative alloys has opened new avenues for manufacturers. These materials not only increase cutting speed but also improve precision, allowing for more intricate designs and detailed workpieces. By utilizing materials engineered for laser interaction, manufacturers can achieve cleaner cuts and reduced kerf, minimizing waste and boosting efficiency.

Moreover, the integration of smart materials with adaptive properties is paving the way for a revolutionary approach to CNC laser cutting. These materials can respond dynamically to changes in temperature and energy input, optimizing the cutting process in real-time. This adaptability not only improves performance but also extends the lifespan of laser cutting equipment. As industries increasingly demand higher quality and faster turnaround times, embracing these advancements in materials is essential for businesses looking to stay competitive and enhance their manufacturing capabilities.

Automation Trends in CNC Laser Cutting: Streamlining Workflow and Reducing Downtime

In the realm of CNC laser cutting, automation is becoming increasingly pivotal in enhancing efficiency and minimizing downtime. As industries demand quicker production cycles and greater precision, the integration of intelligent systems not only streamlines workflow but also ensures a higher output quality. Automation technologies can help manage multiple tasks, from material handling to real-time monitoring, thus allowing operators to focus on more critical areas of production.

Tips for maximizing workflow efficiency with CNC laser cutters include regularly updating software for optimal performance, maintaining equipment to prevent unexpected breakdowns, and investing in training for operators to keep them skilled in the latest technologies. Additionally, leveraging data analytics can provide insights into machine performance, helping to identify bottlenecks in the production process early.

Incorporating innovations such as AI-driven predictive maintenance can greatly reduce downtime. By anticipating equipment failures before they occur, manufacturers can schedule maintenance during off-peak hours and avoid costly production halts. These advancements in automation not only contribute to improved operational efficiency but also position companies to meet the future demands of the manufacturing landscape effectively.

Related Posts

-

Unveiling CO2 Laser Cutting Machines A Detailed Comparison of Efficiency Cost and Precision

-

Ultimate Guide to Choosing the Right Fiber Laser Cutter for Your Manufacturing Needs

-

2025 Market Insights: The Rise of the Best Laser Machine in Precision Manufacturing

-

Ultimate Checklist for Choosing the Right CNC Press Brake for Your Business

-

The Comprehensive Ultimate Guide to Understanding and Choosing the Right Press Brake