Why Understanding Press Brakes is Essential for Metal Fabrication Success

Understanding press brakes is crucial for achieving success in metal fabrication, as they are key tools that shape and bend metal sheets with precision and efficiency. Mastering the operation of press brakes not only enhances the quality of the final products but also streamlines the overall fabrication process. This introductory guide will explore the fundamental aspects of press brakes, including their function, types, and the critical role they play in modern manufacturing. By grasping the intricacies of press brake operations, metal fabricators can optimize their workflows, reduce material wastage, and ultimately improve their competitive edge in the industry. Whether you are a seasoned professional or a newcomer to the field, a solid understanding of press brakes will undoubtedly elevate your craftsmanship and contribute to the success of your metal fabrication projects.

Understanding press brakes is crucial for achieving success in metal fabrication, as they are key tools that shape and bend metal sheets with precision and efficiency. Mastering the operation of press brakes not only enhances the quality of the final products but also streamlines the overall fabrication process. This introductory guide will explore the fundamental aspects of press brakes, including their function, types, and the critical role they play in modern manufacturing. By grasping the intricacies of press brake operations, metal fabricators can optimize their workflows, reduce material wastage, and ultimately improve their competitive edge in the industry. Whether you are a seasoned professional or a newcomer to the field, a solid understanding of press brakes will undoubtedly elevate your craftsmanship and contribute to the success of your metal fabrication projects.

The Critical Role of Press Brakes in Metal Fabrication Processes

Press brakes play a pivotal role in metal fabrication processes, serving as essential tools that enable the precise bending and shaping of metal sheets. Their functionality allows fabricators to create components that meet exact specifications and tolerances, which is crucial in industries ranging from automotive to aerospace. By employing various dies and tools, press brakes facilitate complex shapes that are foundational to high-quality manufacturing.

Moreover, understanding the nuances of press brakes enhances operational efficiency and reduces material waste. Skilled operators can optimize bending sequences and adjust parameters to achieve better outcomes, ultimately leading to significant cost savings. The ability to manipulate different materials and thicknesses further underscores the importance of mastering press brake technology in the fabrication process. Thus, the critical role of press brakes cannot be overstated, as they directly impact the quality, performance, and durability of the final metal products.

Understanding Different Types of Press Brakes and Their Applications

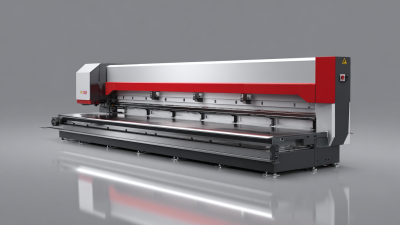

When embarking on a metal fabrication project, understanding the various types of press brakes is crucial for achieving optimal results. There are three primary types: mechanical, hydraulic, and servo-electric press brakes. Mechanical press brakes are well-suited for high-speed applications and are ideal for simpler bends due to their speed and ease of use. Hydraulic press brakes, on the other hand, offer versatility and are highly effective for thicker materials and complex forms. Finally, servo-electric press brakes, which are gaining popularity, combine efficiency and precision, making them perfect for detailed operations with lower energy consumption.

Tips for selecting the right press brake include evaluating the materials you frequently work with and the complexity of your designs. It's essential to match the machine's capabilities with your project requirements. Additionally, consider investing in training for your operators to ensure they are familiar with the specific press brake type and its applications, which can drastically increase productivity and reduce errors. Always remember to keep safety protocols at the forefront to minimize risks when operating any press brake.

To enhance your production efficiency, reviewing maintenance schedules for your equipment is vital. Regular inspections can prevent unexpected downtime caused by mechanical failures. Being proactive with maintenance will not only extend the life of your press brakes but also ensure they operate at peak performance, thus supporting your overall metal fabrication success.

Understanding Press Brakes and Their Applications

Key Features and Specifications to Consider When Choosing a Press Brake

When selecting a press brake for metal fabrication, understanding key features and specifications is crucial for ensuring optimal performance and efficiency. One of the most significant aspects to consider is the tonnage capacity. According to a recent report from the Fabricators & Manufacturers Association (FMA), a press brake’s tonnage rating must align with the thickness and material type being processed; for example, a 100-ton press brake is suitable for making bends in metals up to 1/4-inch thickness. This ensures that the machine can handle the demands of various fabrication tasks.

Another vital consideration is the bend length, which directly impacts the size and complexity of components that can be manufactured. Data from the American Welding Society (AWS) indicates that machines with a bend length of 12 feet or more are increasingly preferred for industrial applications, allowing for the handling of larger sheets and improving production workflows. Additionally, advanced features such as precision tooling and programmable controls can significantly enhance repeatability and reduce setup times, with some modern machines boasting up to a 60% decrease in lead time through automation. Investing in a press brake that incorporates these specifications not only improves product quality but also bolsters overall operational efficiency in metal fabrication.

Why Understanding Press Brakes is Essential for Metal Fabrication Success - Key Features and Specifications to Consider When Choosing a Press Brake

| Feature | Description | Specification |

|---|---|---|

| Machine Type | Determines the bending capabilities based on hydraulic, mechanical or electric systems. | Hydraulic / Mechanical / Electric |

| Bending Length | The maximum length of the workpiece that can be bent. | Up to 16 feet |

| Bending Capacity | The maximum thickness of material the machine can bend. | 0.5 to 1 inch |

| Back Gauge | An important feature for accurate positioning of the workpiece. | Standard / Programmable |

| Control System | User interface to operate the machine efficiently. | CNC / Manual |

| Frame Design | Affects the stability and durability of the press brake. | Open / Closed Frame |

| Maintenance | Ease of maintenance affects downtime and operational efficiency. | Simple / Complex |

Common Challenges in Using Press Brakes and How to Overcome Them

Press brakes are fundamental tools in metal fabrication, but their effective use comes with a unique set of challenges. One common issue is the potential for material deformation during the bending process. According to a report by the Fabricators & Manufacturers Association (FMA), improper setup can lead to up to a 30% increase in waste material due to inaccuracies in bending angles. This not only affects the quality of the end product but also significantly escalates production costs.

Another challenge is the operator's skill level. A survey conducted by the Precision Metalforming Association (PMA) indicated that nearly 40% of manufacturers reported difficulties in finding qualified operators trained in using press brakes. This skills gap can result in lower productivity and higher rework rates. To address these challenges, investing in comprehensive training programs for operators can enhance their understanding of press brake mechanics, leading to more precise operations and reduced waste. Furthermore, implementing mechanical upgrades, such as programmable controls and sensors, can help fabricators achieve better accuracy and efficiency in their processes.

The Future of Press Brakes: Innovations Shaping Metal Fabrication Industry

The future of press brakes is being significantly shaped by innovations that enhance efficiency and precision in the metal fabrication industry. According to a recent report from Research and Markets, the global press brake market is expected to grow at a compound annual growth rate (CAGR) of over 5% through 2028. This growth is fueled by advancements in automation, artificial intelligence, and machine learning, which are transforming traditional pressing methods into more streamlined, intelligent processes.

One of the most promising innovations in press brake technology is the integration of smart software systems that enable real-time monitoring and adjustments during the bending process. These systems not only improve accuracy but also reduce downtime by predicting maintenance needs before failures occur. A study by industry experts forecasts that adopting such smart technologies can increase productivity by up to 30%, allowing fabricators to meet the growing demand for customized solutions in shorter timeframes. As these innovations continue to reshape the landscape, understanding their implications will be crucial for any metal fabrication business looking to maintain a competitive edge.

Related Posts

-

The Comprehensive Ultimate Guide to Understanding and Choosing the Right Press Brake

-

Unveiling CO2 Laser Cutting Machines A Detailed Comparison of Efficiency Cost and Precision

-

What Exactly is a Plasma Cutting Machine and How Does it Transform Metalwork?

-

Essential Checklist for Optimizing Your Fiber Laser Cutting Machine Performance

-

7 Digital Tips for Choosing the Perfect CNC Plasma Cutting Machine for Your Business

-

How to Choose the Best Plasma Cutting Machine for Your Business Needs